OnLine Catalogues

- Arms systems

- Box Systems

- Drops Arm Kit

- vertical awning systems

- General accessories for retractable awnings

- Versiplan Pro System

- Flat Awning System

- Pergo Rain simple unit

- Pergo Rain double unit

- Pergo Rain Triple unit

- Pergo Rain Built In simple unit

- Pergo Rain Built In double unit

- Pergo Rain Built In Triple unit

- Pergo Rain Plus

- Pergo Rain Plus Built-IN

- Atmosphere simple unit

- Atmosphere double unit

- Atmosphere Triple unit

- Atmosphere Built-in simple unit

- Atmosphere Built-in double unit

- Atmosphere Built-in Triple unit

- Pergoglam Simple Unit Perimeter Structure

- Pergoglam Double Unit Perimeter Structure

- Pergoglam Triple Unit Perimeter Structure

- Pergoglam Simple Unit Wall Mounted Structure

- Pergoglam Double Unit Wall Mounted Structure

- Pergoglam Triple Unit Wall Mounted Structure

- Pergoglam Simple Unit Free Standing Structure

- Pergoglam Doble Unit Free Standing Structure

- Pergoglam Triple Unit Free Standing Structure

- Atica System Simple Unit Bulit-In

- Atica System Double Unit Bulit-In

- Atica System Simple Unit Wall Mounted Structure

- Atica System Double Unit Wall Mounted Structure

- Atica System Simple Unit Free Standing Structure

- Atica System Double Unit Free Standing Structure

- Atica System Double Unit Free Standing Structure

- Atica System Double Unit Free Standing Structure

- LED Lighting Pergorain System

- Perimeter LED Lighting Atica System / Pergoglam

- Lighting Led Spotlights Atica System / Pergoglam

- Sound / Climate Control Atica System / Pergoglam

- Flat Awning System

- Pergola Accesories

- Other Accessories

- Teka Flat Awning System

- Motors

Informative Brochure

PDF Catalogue

Raw materials and processes

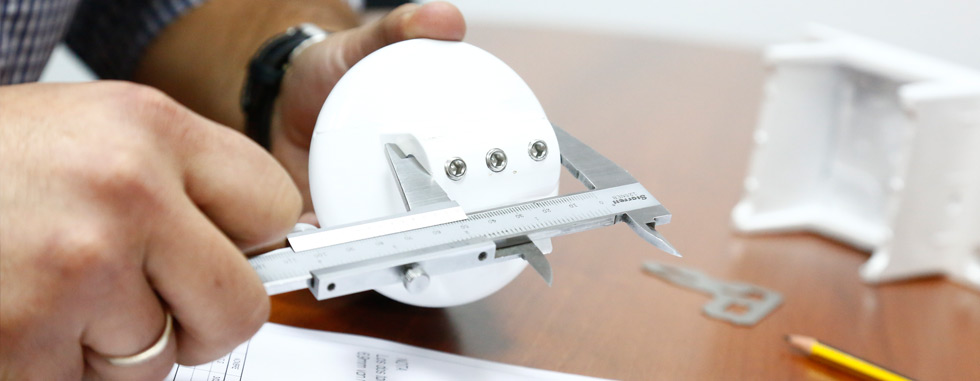

With the aim of achieving the reliability of our pergolas and awnings, the materials are controlled from the first phases with our own production lines of:

- Extrusion, with one of the largest and most technical presses in Europe.

- Gravity casting, which ensures parts with perfect balance between resistance and elasticity.

- Aluminium injection, which allows us to achieve great competitiveness

- 2 lacquering plants, one vertical for large volumes of profiles and another horizontal one for complete accessories and products in colours; both with high corrosion-resistant finishes

- Robotic mechanization systems, which allow us to obtain great precision and speed.

In our manufacturing process, all accessories are treated in the shot-blasting section, giving them the surface finish necessary for the subsequent lacquering process. In this process, parts and profiles pass through a 5-stage chemical treatment tunnel, where they are subjected to acidic degreasing, rinsing and application of product to obtain an unbeatable anti-corrosion protection. Subsequently, parts and profiles pass through the automatic paint booth and finally, through the polymerization tunnel, where they acquire the definitive surface finish. The aim is to guarantee a high corrosion-resistant lacquer under the most unfavourable environmental conditions.

In the following step of mechanization and assembly, the product is subjected to the machining process to obtain the fit and assembly that makes SIPLAN pergolas and awnings a reliable and durable product.

The way of presenting the packaged product makes storage and distribution easier.

SEDE SOCIAL

Polígono Gandul

Calle Pintores 27.

41510 Mairena del Alcor

(Sevilla) España.

DEP. DE EXPORTACIÓN

Polígono Centrovía

Avda de los Ángeles, 2-4.

50196 La Muela (Zaragoza).

Sevilla: Plg. Gandul C/Pintores 27. 41510 Mairena del Alcor (Sevilla)

Zaragoza: Avda. de los Ángeles, 2-4. Polígono Centrovía La Muela (Zaragoza)

Canarias:Ctra del Rosario nº41 Plg Luz & Cia Nave 22, 38108 Taco La Laguna.